- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

Brand Name : DONHO

Model Number : DHVMC-850

Certification : GS , CE , ROHS , ISO

Place of Origin : CHINA

MOQ : 1 SET

Price : Negotiable

Payment Terms : T/T, L/C

Supply Ability : 200 piece per month

Delivery Time : 2 weeks after balance

Packaging Details : 1.Whole film packaging machine; 2.Anti-collision package edge; 3.Fumigation-free plywood wooden box with iron binding belt.

Product name : CNC Milling machine

After-sales service provided : Engineers available to service machinery overseas

Power(w) : 7.5/11 kW

Spindle : 7.5 KW FANUC Spindle Motor

Inner structure : Very steady

Machine type : China manufacturer machining center cnc vertical process center

Weight : 4800kg

Dimension(l*w*h) : 2300*2100*2500mm

Warranty : 2 Years

Voltage : Customer's Requirement

Automatic Lubrication System Full Cover Shroud Cnc Vertical Machining Center For Iron Ore Engraving

Advantage

1. easy to use;

2. Taiwan-made spindle: The main body is assembled with P4 bearing to ensure low vibration of each speed;

3. New low-loss power components for energy savings;

4. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts;

5. Easy accessibility of work table for easy setup and tooling;

6. Funnel type 20-station tool changer for quick and precise tool changes (as Optional);

7. Urgent stop button in set on the CNC machine center body, it is for easy. It is convenient installing and regulating.

Specifications

| Type | unit | DHVMC-850 | |

| Table | Table size | mm | 1000*500 |

| Max. load of worktable | kg | 400 | |

| T slot no./width/distance | mm | 18x5x90 | |

| Travel | X axis travel | mm | 800 |

| Y Axis travel | mm | 500 | |

| Vertical travel | mm | 500 | |

| Spindle | spindle nose to table surface | mm | 150-650 |

| spidle axis to column surface | mm | 572 | |

| Speed Range | rpm | 10,000 | |

| Spindle taper | Type | BT-40 | |

| Spindle head casing aperture | mm | φ140mm | |

| Spindle driver | - | Belt transmission | |

| Auto tools change | Maximum tool diameter | mm | Φ80(Φ130) |

| Maximum tool length | mm | 300 | |

| Maximum tool weight | kg | 8 | |

| Shank | Type | BT-40 | |

| Tool magazine capacity | Pieces | 24 | |

| Tool exchange method | - | Knife arm | |

| Tool exchange time (knife-to-knife) | Sec | 1.8 | |

| Rivet | Type | P40-1( 45°) | |

| Motor capacity | Controller | Syntec 22MA | |

| Spindle motor (continuous / 15 minutes) | kW | 7.5/11 | |

| Servo motor (X/Y/Z) | kW | 2.6/2.6/3.0 | |

| Automatic lubrication device | w | 35 | |

| Cutting fluid pump | w | 840 | |

| battery capacity | kVA | 25 | |

| Others | Air source pressure demand | kg/cm | 6 |

| Cutting water tank capacity | L | 250 | |

| positioning accuracy | mm | 0.01 | |

| Repeatability accuracy | mm | 0.008 | |

| Floor area and height | mm | 2550*2250*2400 | |

| Machine weight | kg | 5000 | |

Machine Details

Series 0i-MODEL F

FANUC proposes a new method that combines analysis of machining programs and application of functions suitable for it, in place of the cycle time reduction methods that have been explored so far.

The Servo Guide is a servo adjustment tool (PC software) that promotes "visualization" of the machine. This time, a function has been added to analyze the operation of CNC at the time of processing program execution. With this function, the operation of the CNC can also be “visualized”, and it is possible to understand which part of the machining program is taking time. Based on the analysis results, it is possible to centrally manage and collectively set various cycle time reduction functions using the newly developed processing time reduction setting screen. Furthermore, the smart overlap function that optimizes the feed time and the FSSB high-speed rigid tap function that speeds up the threading can be added, making it possible to apply the optimum speed-up method to various machine tools.

Oil cooled system for spindle

1. Oil temperature control is based on the body temperature (room temperature). The user can set the oil temperature according to the temperature of the body to prevent thermal deformation of the mechanical structure.

2. Immersed oil cooling and temperature control device is free from impurities, is not interfered by cutting metal powder, etc. It is easy to clean and easy to maintain; it is easy to install and does not take up space.

3, with automatic fault alarm function, can promptly remind the user to repair the device in a specific way, so as to avoid damage to the machine.

FANUC Servo amplifier

Amplifier for driving servo motors and spindle motors;

A stand-alone structure makes it easy to achieve an optimized combination of amplifiers based on power supply capacity;

High processing performance;

Equipped with intelligent rigid tapping function that is effective in shortening processing time;

High operating rate;

The product contains 200V and 400V power supply specifications for customers to choose.

Fully enclosed tool magazine

the processing environment is noisy and it is not easy to enter the iron filings. Guarantee the service life of the tool magazine, reduce tool change failure, extend the service life of the spindle, and ensure the precision of machining.

Auto Chip conveyor

The device has the advantages of serialization, generalization and standardization, simple operation, reliable operation, convenient disassembly and assembly, and easy maintenance. It can also be used in conjunction with other chip evacuation devices to form a variety of cutting arrangements.

1. It can handle all kinds of chips; it can also be used as a conveying device for small parts of stamping and cold pier machine tools.

2. With overload protection;

3. The width of the chain plate is diversified, and the structural form is divided into two types: a seamless chain plate and a seam chain plate. 4, streamlined shape, beautiful appearance, smooth chip removal.

4. High conveying efficiency and large selection range of conveying speed.

Hiwin rail

Due to the rolling friction method, when the linear guide is used as the linear guide, not only the friction coefficient is reduced to 1/50 of the sliding guide, but also the difference between the dynamic friction and the static friction is small. Therefore, when the bed is running, there is no slippage, the positioning accuracy of μm can be achieved, and the machine can maintain the accuracy for a long time. The power loss of the machine can be significantly reduced, and the heat generated by the friction is small, which is suitable for high-speed operation. The special beam structure design can bear the load in the up, down, left and right directions at the same time. Easy to assemble, it maintains accuracy and is interchangeable, allowing you to replace sliders or rails or even linear guide sets. The lubrication structure is simple and easy to oil.

Triaxial slide rail retractor

The machine guard is used to protect the machine guide rails. He protects the machine's internal hard rails, linear guides and ball screws or drive racks from external corrosion and damage. It can effectively prevent the entry of chips and other sharp objects, and can effectively reduce the penetration of coolant through certain structural measures and suitable scraping plates.

The steel plate shield has a good seal and can prevent iron filings, anti-cooling liquid and anti-tool accidents.

1. Sturdy and durable, stable operation, low noise and beautiful appearance.

2, steel plate shield is suitable for high-speed motion machine tool rail protection is stable and no vibration noise.

3. The steel plate cover device not only protects the service life of the guard plate, but more importantly ensures the precision of the machine tool.

4. Each guard plate of the steel plate shield is pulled apart in parallel at the same time, and is simultaneously retracted in parallel, and runs freely.

5, the steel plate shield will not make the guard plate disjointed, there is impact sound, both beautiful and improve the service life of the guard plate.

6. On the basis of the original sealing strip, a layer of stainless steel cover is added to prevent the high temperature burn strip of iron filings from rubbing into the rail surface and pulling the guide rail.

Auto Chip conveyor

The device has the advantages of serialization, generalization and standardization, simple operation, reliable operation, convenient disassembly and assembly, and easy maintenance. It can also be used in conjunction with other chip evacuation devices to form a variety of cutting arrangements.

1. It can handle all kinds of chips; it can also be used as a conveying device for small parts of stamping and cold pier machine tools.

2. High conveying efficiency and large selection range of conveying speed;

3. The width of the chain plate is diversified, and the structural form is divided into two types: a seamless chain plate and a seam chain plate. 4, streamlined shape, beautiful appearance, smooth chip removal.

4. With overload protection.

|

|

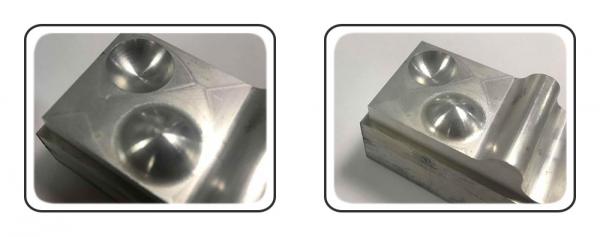

Full Cover Shroud CNC Vertical Machining Center For Iron Ore Engraving Images |